The Global Textile & Apparel Industry Explained: A Simple Guide

The Global Journey of Your Clothes: Understanding the Textile & Apparel Industry

Have you ever looked at the tag on your shirt and wondered how it traveled from a cotton field or a chemical plant to your wardrobe? That simple tag tells the end of a remarkable global story. The textile and apparel industry—the world of fabrics and clothing—is one of the largest and most interconnected sectors on the planet. It employs hundreds of millions of people, from farmers to fashion designers, and touches the lives of every single consumer. This guide breaks down this complex world into easy-to-understand parts, exploring how it works, the challenges it faces, and the exciting changes on the horizon.

What's Inside This Guide?

The story of a simple garment is often a trip around the world.

How Big Is This Industry Really?

Let's start with the numbers. The global market for textiles and clothing is worth over 2.5 trillion dollars. To put that in perspective, if it were a country's economy, it would be one of the top 10 largest in the world. It's responsible for about 1.6% of the entire world's economic output (GDP).

But it's not just about money; it's about people. An estimated 430 million individuals work in this sector. That includes everyone from the woman picking cotton in Texas, to the engineer running a high-tech fabric mill in Germany, to the sales assistant in a mall in Tokyo. It's a major source of jobs, especially in developing countries where manufacturing clothes is often one of the first steps into industrial work.

Consumption is huge, too. The world buys nearly 120 billion new garments every year. That's about 15 items for every person on Earth. This incredible scale is what makes the industry so powerful, but also why its social and environmental impact is so significant.

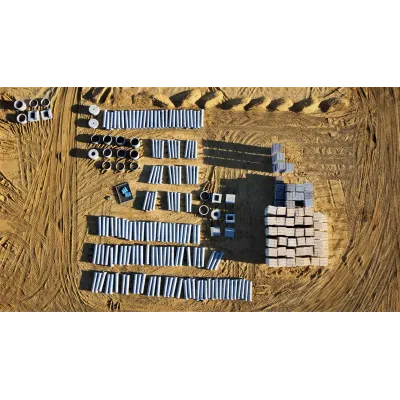

The Supply Chain: From Field to Hanger

Making clothes is not a simple, one-step process. It's a long chain of events, often spread across multiple countries. This chain is called a "global supply chain." Think of it like a relay race where the baton (the material) is passed from one specialist to another.

The Four Major Stages:

1. Sourcing Raw Materials

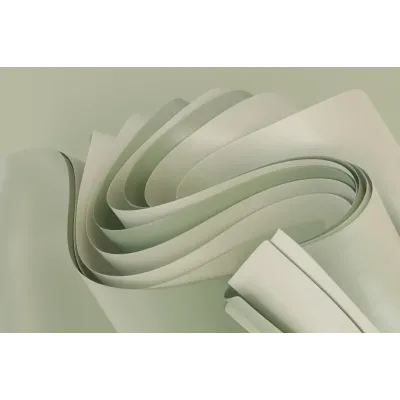

This is where it all begins. Natural fibers like cotton, wool, and silk come from plants and animals. Synthetic fibers like polyester and nylon are made from chemicals, usually derived from oil. Today, over 60% of all our clothes are made from synthetic materials like polyester because they are cheap and versatile.

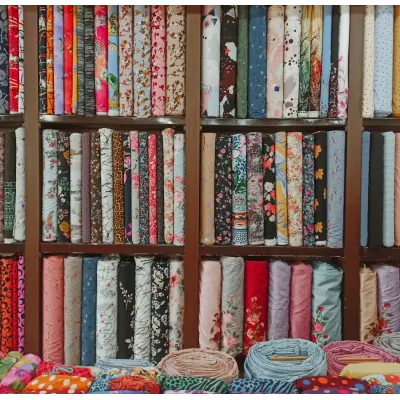

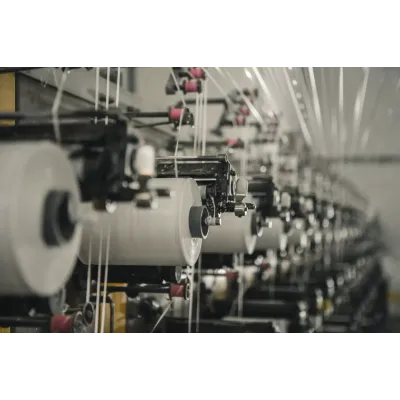

2. Making Yarn and Fabric

Fibers are cleaned, straightened, and spun into yarn (thread). That yarn is then woven or knitted into fabric. This fabric is then dyed, printed on, or treated with chemicals to make it soft, waterproof, or wrinkle-resistant. This stage uses a lot of water and energy.

3. Manufacturing the Garment

Here, fabric is cut into pieces based on patterns and sewn together into the clothes we recognize. This is very detailed work that, until recently, has been difficult to automate. It requires a lot of skilled human labor, which is why this step often takes place in countries with lower labor costs.

4. Branding, Selling & Wearing

The finished clothes are shipped to brands and retailers around the world. They are marketed, sold in stores or online, and finally reach you, the consumer. This last step is where most of a garment's final price tag comes from, covering design, marketing, rent, and profit.

Who Makes What? Key Players & Places

The industry has a clear geographic footprint shaped by costs, skills, and trade rules.

Asia is the factory floor. China remains the single largest producer, making about one-third of the world's clothing exports. Countries like Bangladesh, Vietnam, and India are also massive hubs for garment sewing, offering the large workforce needed for this labor-intensive stage.

The US and Europe are leaders in consumption and high-tech textiles. While they import most of their basic apparel, they excel in other areas. The United States is a top producer of cotton and a leader in inventing high-performance "technical textiles" used for things like medical implants, firefighter gear, and car interiors. European brands are often at the forefront of fashion design and sustainability efforts.

This global division of labor means a typical pair of jeans might use cotton from the US, be woven and dyed in China, sewn in Bangladesh, and sold by a European brand in an American store. It's a truly interconnected system.

Big Challenges: Cost, Planet & Transparency

Such a large and spread-out industry faces some tough problems. Three of the biggest are cost pressure, environmental impact, and a lack of transparency.

1. The Race to the Bottom on Cost

For decades, brands have sought the lowest possible production costs to offer cheap, fast fashion to consumers. This constant pressure can squeeze factory profits, leading to challenges in maintaining fair wages and safe working conditions. It also encourages moving production to new regions as wages rise in existing ones.

Skilled labor remains the core of garment manufacturing worldwide.

2. The Heavy Environmental Footprint

The industry has a significant impact on our planet:

- Climate Change: It's responsible for an estimated 2-4% of all global carbon emissions—more than international flights and shipping combined.

- Water and Pollution: Dyeing and treating fabric uses massive amounts of water and can pollute rivers if wastewater isn't treated properly.

- Waste: We throw away clothes at an alarming rate. A truckload of textiles is landfilled or burned every single second. Less than 1% of old clothes are recycled into new ones.

Governments are starting to act. The European Union, for example, is creating strict new laws to make clothes more durable, repairable, and recyclable.

3. The "Black Box" Supply Chain

When a brand sources from hundreds of factories, which in turn buy from thousands of suppliers, it becomes very hard to see what's happening at the beginning of the chain. Can a brand be sure the cotton wasn't picked with forced labor? Or that the dye house isn't polluting a local river? This lack of visibility is called the "transparency gap." Closing this gap is a huge challenge that requires better tracking, honest reporting, and independent verification. Resources like those offered by organizations focused on verification are becoming increasingly important in this effort.

What's Next? Trends Shaping the Future

In response to these challenges, the industry is innovating and changing. Here are three key trends to watch:

The Rise of Circular Fashion

The old "take, make, waste" model is being challenged. The goal of circular fashion is to keep materials in use for as long as possible. This means designing clothes to last, offering repair services, renting clothes, and—crucially—recycling old garments into new fibers. While still in its early days, this shift is essential for reducing waste and pollution.

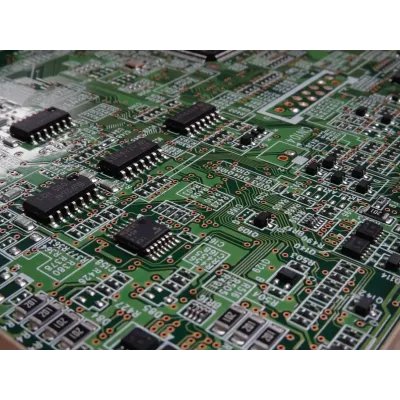

Smarter Clothes & Smarter Factories

Technology is entering the fold. Smart textiles include fabrics that can monitor your heart rate, change color, or even harvest energy from the sun. In factories, automation and robots are beginning to help with cutting and sewing, which could bring some manufacturing back to countries with higher wages. Artificial intelligence is also used to predict fashion trends and manage inventory more efficiently.

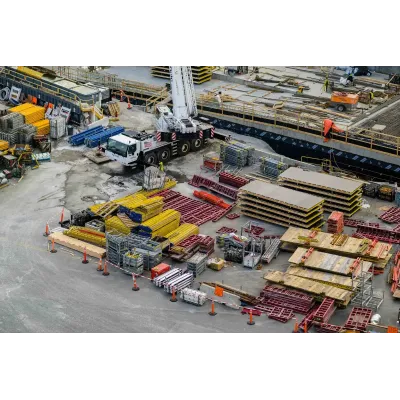

Reshaping Global Supply Chains

Recent disruptions have shown the risk of relying too much on one region. Many brands are now looking to diversify their sourcing—a strategy called "friendshoring" or "nearshoring." This means producing closer to where the clothes will be sold, like making clothes for the US market in Mexico or Central America. This can reduce shipping times, costs, and carbon footprint, while also making supply chains more resilient.

The future lies in balancing high-tech innovation with nature-positive practices.

Why Understanding This Matters

You might wonder why all this detail about a single industry matters. The truth is, the choices this industry makes—and the choices we make as consumers—have real-world impacts.

Understanding where clothes come from helps us appreciate the skill and effort of millions of people. It also empowers us to ask better questions: Who made my clothes? What are they made of? How long are they designed to last? This knowledge is the first step towards supporting brands that treat people and the planet fairly.

The global textile and apparel industry is on a journey of transformation. It's moving from a model focused solely on low cost and speed to one that must also prioritize sustainability, ethics, and resilience. For businesses, navigating this new landscape requires reliable information and trusted partners. For all of us, it starts with a simple act of curiosity about the story behind the tag.

Want to learn more about building transparency in global industries? Explore our insights on how verification is shaping the future of responsible business.

-450x250h.webp)

-150x150h.webp)

Leave a Comment