Building Materials Industry: A Complete Guide to How It Works in 2026

Table of Contents

Look around you. The home you live in, the office you work in, the bridges you cross, and the roads you travel—they all exist because of the building materials industry. This vast, global sector is the silent foundation of our modern world. It's not just about bricks and mortar; it's a complex network that turns raw materials from the earth into the safe, sturdy structures we depend on every day. From the wood in your roof to the glass in your windows and the concrete in your foundation, this industry shapes the very spaces where we live, work, and connect.

What is the Building Materials Industry?

Think of it as the world's supplier for construction. It's the entire ecosystem responsible for producing, processing, and delivering every single material used to build or renovate any structure. This includes two main categories:

- Natural Materials: These come directly from the environment, like timber from forests, stone from quarries, sand and gravel from pits, and clay from deposits.

- Manufactured Materials: These are created through industrial processes. This group includes heavyweights like cement, concrete, steel, brick, glass, and plastics, as well as thousands of specialty products like insulation, paints, adhesives, and waterproofing membranes.

The scale is almost hard to grasp. To put it in perspective, the global building materials market is a multi-trillion-dollar engine. Recent analyses suggest it was valued at over $1.4 trillion in 2024 and is steadily growing, potentially reaching over $2 trillion by the early 2030s. This growth is fueled by global needs: new homes for growing populations, modern offices for businesses, and critical infrastructure like roads, bridges, and airports in both developed and developing nations.

But there's another, crucial side to the story. This industry is deeply connected to some of our biggest global challenges. The construction and operation of buildings are responsible for a significant portion of the world's energy consumption and greenhouse gas emissions. This has placed the building materials sector right at the heart of the conversation on climate change. Every new law about energy efficiency, every corporate sustainability goal, and every innovation in green design directly influences what materials are made and how they are produced.

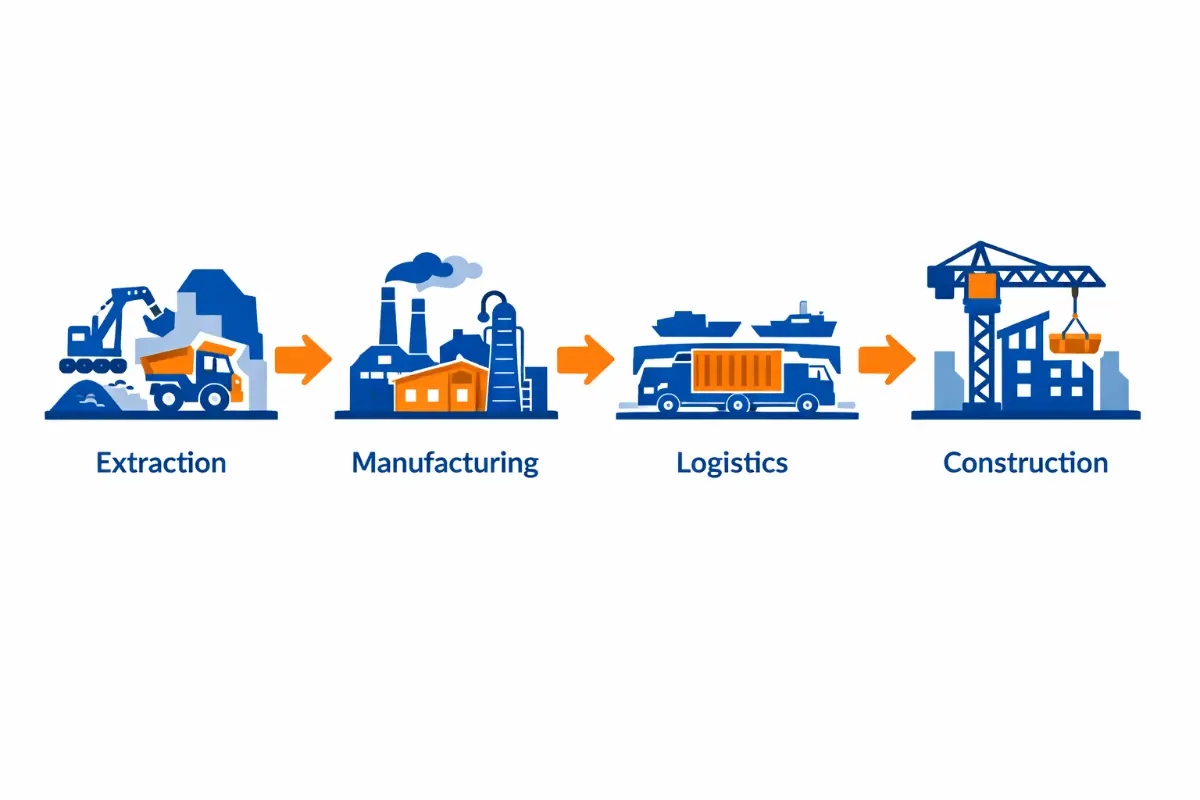

How It Works: From Quarry to Construction Site

The journey of a building material from its origin to its final place in a structure is a long and fascinating chain of events, often called the value chain. Understanding this flow shows just how much effort and coordination goes into creating our built environment.

1. Extraction: Getting the Raw Stuff

It all starts with what we can take from the earth. This stage involves mining, quarrying, and harvesting.

- Quarries provide the essential bedrock: limestone for cement, granite and marble for dimension stone, and slate for roofing.

- Mines and Pits yield clays for bricks, gypsum for wallboard, and vast quantities of sand and gravel—which, by volume, are among the most extracted materials on the planet and are crucial for making concrete.

- Forests are managed to produce lumber, plywood, and engineered wood products.

2. Manufacturing: The Transformation

Here, raw materials are transformed through energy-intensive and often complex processes.

- Cement: Limestone and clay are crushed, mixed, and fed into a giant rotating kiln heated to about 1,450°C (2,642°F). This process, called calcination, creates "clinker," which is then ground with a little gypsum to become the fine powder we know as cement.

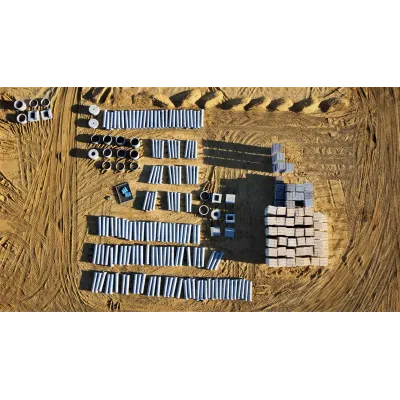

- Concrete: Cement is mixed with water, sand (fine aggregate), and gravel (coarse aggregate) to form concrete. This can be done at a central plant and delivered in rotating drum trucks as "ready-mix," or it can be formed into pre-cast shapes like walls, beams, or pipes in a factory.

- Steel: Iron ore is smelted in blast furnaces and then refined. Recycled scrap metal is also a major feedstock in electric arc furnaces, making steel one of the world's most recycled materials.

- Glass: Sand (silica) is melted at extremely high temperatures with other additives, then floated on a bed of molten tin to create perfectly flat sheets, or blown and molded into other shapes.

3. Distribution: The Heavy Lift

Getting heavy, bulky, and sometimes fragile materials to thousands of construction sites is a logistical marathon. Because transportation costs are high relative to the value of basic materials like aggregates, operations are often regional. You'll see:

- Networks of local ready-mix concrete plants serving a specific city or area.

- Specialized distributors and mega-retailers that stock everything from lumber and roofing to nails, tools, and paints for professional builders and DIYers.

- Complex planning to ensure just-in-time delivery, so that perishable materials like concrete arrive exactly when the construction crew is ready to pour.

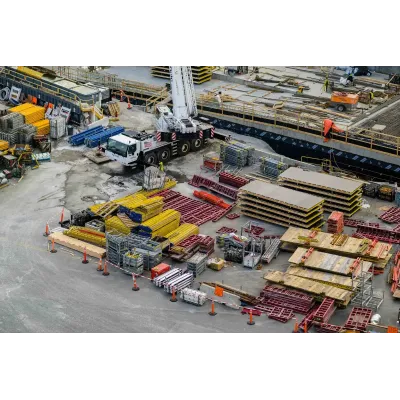

4. Application: Where It All Comes Together

This is the final stage, where architects' visions and engineers' calculations become reality. General contractors and specialized tradespeople—masons, carpenters, steelworkers, glaziers—take the delivered materials and assemble them according to detailed plans and strict building codes. The quality of application is just as important as the quality of the material itself for ensuring a safe, durable, and functional building.

Key Players: Who Builds Our World?

The industry isn't dominated by one single type of company. Instead, it's a mix of giants, specialists, and essential connectors, each playing a distinct role.

- The Vertically Integrated Giants: These are massive corporations like Holcim (Switzerland), CRH (Ireland), and CEMEX (Mexico). They often control much of the chain themselves, owning the quarries for aggregates and limestone, operating the cement plants, and running ready-mix concrete and asphalt businesses. This gives them control over cost and supply. Chinese firms like China National Building Material (CNBM) and Anhui Conch are also titans in this space, reflecting the immense scale of construction in Asia.

- The Material Champions: These companies are world leaders in a specific type of material.

- ArcelorMittal is the globe's leading steel producer.

- Saint-Gobain is a powerhouse in glass, insulation, and interior products.

- Sherwin-Williams dominates the paints and coatings market.

- Companies like Vulcan Materials and Martin Marietta in the U.S. are focused primarily on aggregates (crushed stone, sand, gravel).

- The Innovation Enablers (Chemical & Tech): This segment includes firms like Sika, MBCC Group, and BASF. They don't make the bulk materials, but they make the advanced chemicals and additives that give them superpowers: admixtures that make concrete flow easier or set faster, waterproofing systems, high-strength adhesives, and corrosion inhibitors. Their products are critical for modern, high-performance, and durable construction.

- The Distributors & Retailers: Often the face of the industry for smaller builders and homeowners, companies like Ferguson (plumbing), Builders FirstSource, or big-box stores provide the crucial last-mile link in the supply chain.

Today, evaluating these players involves looking at more than just their size or revenue. For architects choosing sustainable products, for cities setting green building standards, or for investors assessing risk, factors like a company's carbon footprint, its worker safety record, its investment in recycling and circular economy initiatives, and the transparency of its supply chain are becoming equally important parts of the picture.

Big Trends Shaping the Future

The industry is not static. Powerful forces are pushing it to evolve faster than ever before.

The Green and Circular Revolution

This is the overarching megatrend. The goal is to reduce the "embodied carbon"—the emissions locked into making the materials—of everything we build.

- Decarbonizing Conventional Materials: The biggest challenge. This includes using alternative fuels (like biomass) in cement kilns, developing new cement chemistries that require less limestone, incorporating industrial by-products (like fly ash from power plants) into concrete, and using more recycled steel.

- Bio-based Materials: A fast-growing frontier. Imagine insulation grown from mushroom roots (mycelium), wall panels made from fast-growing hemp or straw, and structural beams from engineered bamboo. These materials often "lock away" carbon as they grow and are typically renewable and biodegradable.

- Carbon Capture, Utilization, and Storage (CCUS): A high-tech solution being piloted at cement plants. It involves capturing CO2 emissions from the production process and either storing them safely underground or, even better, using them—for example, injecting CO2 into fresh concrete where it becomes permanently trapped and can even make the concrete stronger.

The Digital and Smart Makeover

Technology is making construction smarter and more efficient.

- AI and Generative Design: Algorithms can now help design structures that use the absolute minimum amount of material needed for strength, reducing waste from the very first sketch.

- Smart Materials: These are materials that can react to their environment. "Self-healing" concrete contains bacteria or capsules that seal tiny cracks when water enters. Electrochromic glass can tint on command to control heat and light.

- 3D Printing (Additive Construction): While still emerging, large-scale 3D printers can create entire walls or small houses by layering concrete or other composites. This allows for complex, custom shapes and can reduce labor and formwork waste.

Modern Methods of Construction (MMC)

This trend moves more work from the messy, weather-dependent construction site into a controlled factory setting.

- Prefabrication & Modular Building: Whole rooms or sections of a building (modules) are built in a factory, complete with wiring and plumbing, then shipped to the site and stacked or assembled. This leads to faster build times, higher quality control, and significantly less on-site waste.

- Lightweighting: Using advanced materials like cross-laminated timber (CLT) for mid-rise buildings or high-strength, lightweight composites. This reduces the load on foundations, allows for easier transport, and can lower the overall carbon footprint of a structure.

Challenges the Industry Faces

Transforming such a massive, established industry is filled with obstacles.

- Cost Volatility and Margin Pressure: The prices of key inputs like lumber, steel, resins, and energy can swing wildly due to geopolitical events, trade disputes, and natural disasters. A prominent consulting firm highlighted that many companies struggle with "agile margin management," finding it hard to adjust prices and contracts quickly enough when their own costs spike unexpectedly.

- Fragmented and Strained Supply Chains: The industry relies on a long, interconnected global network. A delay at a port, a shortage of truck drivers, or a factory shutdown can ripple through and stall projects worldwide. Building resilience into these chains is a constant effort.

- The Innovation Adoption Gap: While exciting new materials and technologies are developed in labs, getting them accepted by conservative building codes, trusted by contractors, and produced at a competitive scale is a slow and difficult process.

- Skills and Labor Shortages: In many countries, there is a shrinking pool of skilled tradespeople (masons, carpenters, etc.). This pushes the industry toward more prefabrication and automation but also creates a workforce training challenge.

- Regulatory Complexity: Companies must navigate an ever-growing web of local, national, and international regulations concerning safety, emissions, energy performance, and material sourcing. Staying compliant while remaining competitive is a tightrope walk.

Looking Ahead

The building materials industry stands at a pivotal moment. Its core mission—to provide the physical substance for human progress—remains unchanged. But how it fulfills that mission is undergoing a profound transformation. The drive for sustainability is no longer a niche concern but a central business imperative. Digital tools are unlocking new levels of efficiency and performance.

The choices made by this industry in the coming decade will literally shape our future landscape and directly impact our global climate goals. For anyone interested in the future of cities, business, or the environment, understanding the dynamics of this foundational sector is not just informative—it's essential.

-450x250h.webp)

-150x150h.webp)

Leave a Comment